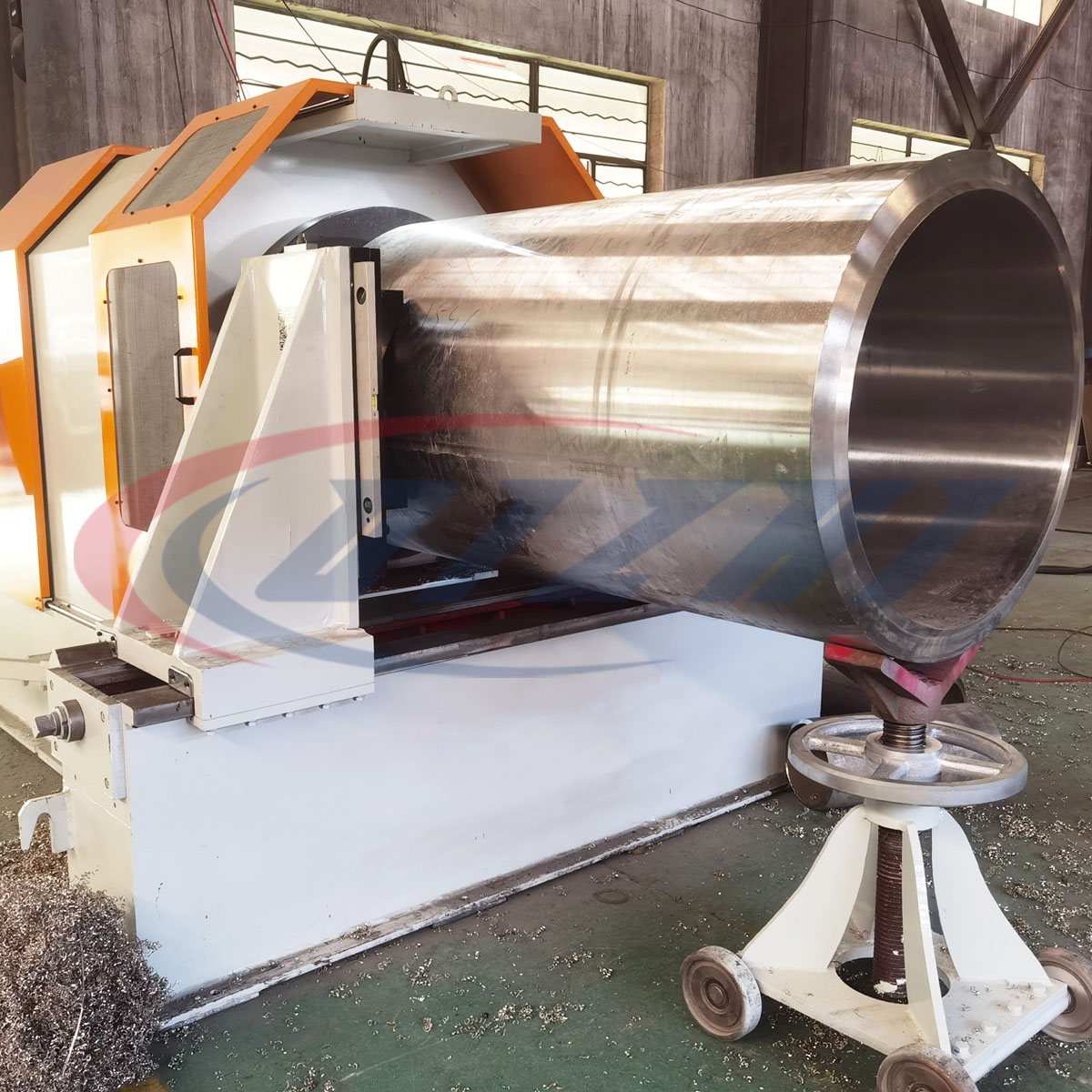

Specifications

| Model | QZ PEB-16 | QZ PEB-24 | QZ PEB-32 | QZ PEB-40 | QZ PEB-48 | QZ PEB-60 |

| Suitable for pipe size | DN50-400 | DN100-600 | DN100-800 | DN200-1000 | DN300-1200 | DN600-1500 |

| Suitable for pipe materials | CS, ALS, SS, duplex SS, low-temperature steel, heat-resistant steel, etc. | |||||

| Suitable for pipe thickness | 5-60mm | 6-120mm | 6-120mm | 8-120mm | 8-120mm | 8-120mm |

| Machine power | 11KW | 13KW | 13KW | 16.5KW | 16.5KW | 21KW |

| Cutter rotating speed/rpm | 0-200 | 0-160 | 0-160 | 0-80 | 0-80 | 0-60 |

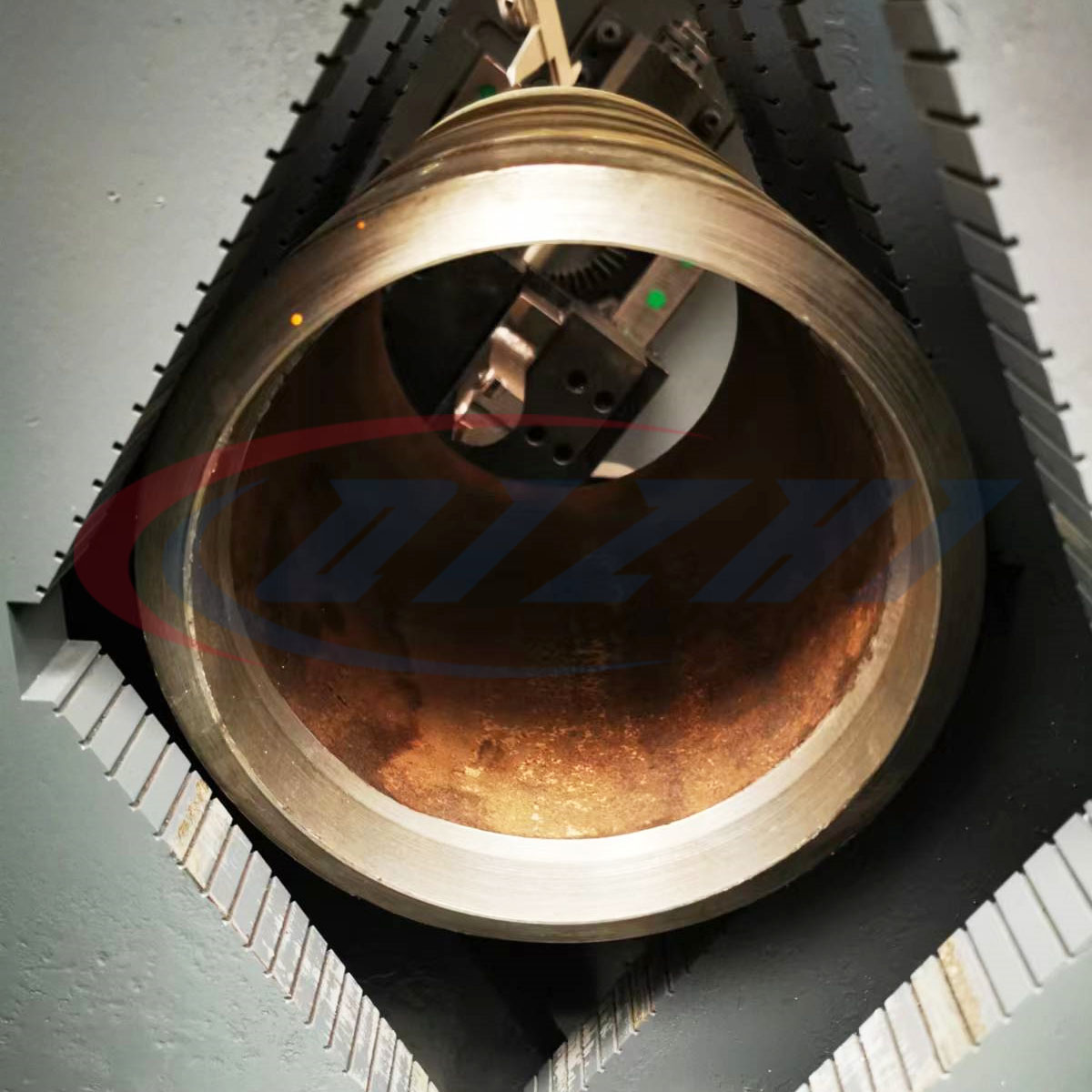

| Bevel types | I type, V type, J type, compound V type, V+J type, internal beveling, or customized based user's requirement | |||||

| Processing mode | 3-axis simultaneous-motion, Mitsubishi or Siemens CNC system | |||||

| Clamping mode | Hydraulic self-centering | |||||

Write your message here and send it to us